Pump Guide

Pump Selection Guide

- Gather your application data first. The following data is important:

- Fluid to be pumped and its physical and chemical characteristics

- Viscosity

- pH value

- Specific Gravity

- Size of suspended solids, if any

- Discharge rate required

- Head at which discharge is required

- Suction head, if any

- Pipeline diameter intended/existing and no. of bends

- Fluid to be pumped and its physical and chemical characteristics

- Select the diaphragm. Teryair® offers the following material choices:

- Neoprene

- An excellent general-purpose diaphragm for non-aggressive applications such as water-based slurries, well water or seawater. It exhibits excellent flex life and is affordable.

- Temperature range -18 C to +93 C (0 F to +200 F)

- Nitrile

- Excellent for applications involving petroleum / oil-based fluids such as leaded gasoline, fuel oils, non-synthetic hydraulic oils, kerosene, turpentine and motor oils.

- Temperature range -12 C to +82 C (+100 F to +180 F)

- Viton®

- Excellent for use in applications requiring extremely hot temperatures. It may also be used with aggressive fluids such as aromatic or chlorinated hydrocarbons and highly aggressive acids—especially where high suction lift is important.

- Temperature range -40 C to +175 C (-40 F to + 350 F)

- PTFE

- An excellent choice when pumping highly aggressive fluids such as aromatic or chlorinated hydrocarbons, acids, caustics, ketones and acetates.

- Temperature range +4 C to +104 C (+40 F to +220 F)

- Santoprene™

- Good abrasion resistance. Low cost. Can handle mild acids and alkalis well—excellent low-cost alternative to PFTE. Excellent suction capabilities Excellent general-purpose diaphragm.

- Temperature range -40 C to +107 C (-40 F to +225 F)

- Hytrel®

- Good abrasion resistance. Low cost. Excellent suction capabilities Excellent general-purpose diaphragm.

- Temperature range -27 C to +107 C (-40 F to +225 F)

- Neoprene

- Once the diaphragm material is chosen, select the correct material for construction of the pump. Teryair® offers the following material options:

- Aluminum

- Good for fluids having pH between 5.5 and 8.5. Temperature is only limited by diaphragm limits

- Stainless Steel 316L

- Good for stronger concentrated acids and alkaline fluids. Stainless Steel is durable and rugged.

- Temperature is only limited by diaphragm limits

- Polypropylene

- Good alternative low-cost choice where fluid is compatible, especially chemical compatibility and temperatures.

- Polypropylene is good between Temperature ranges of +12 C to +107 C and +32 F to +175 F.

- Ductile Iron

- Ideal for underground and overground rugged duty, especially where underground duty calls for a no-aluminum construction. Economical alternative to SS in these cases.

- Aluminum

- Now establish the TOTAL Head using the below calculation.

- TOTAL Head = Specific gravity X (Suction Head + Discharge head)

- Add roughly 10 feet for each 90-degree bend, allowing for friction within the pipe.

- Check Solids Handling Capability

- The maximum slurry particle size must not exceed the pump’s solids passage capability. A strainer may be placed on the inlet line to eliminate particles larger than the pump’s capability.

- Please refer to individual specifications for your pump’s specific solids passage capabilities.

- Choose the best pump model for your needs

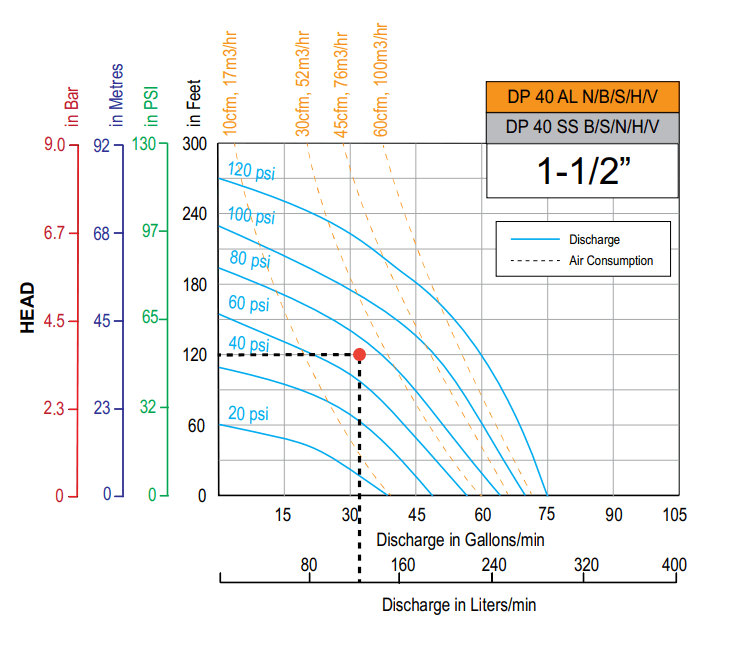

- Example: To achieve a flow of 120 liters per minute at a head of 120 feet.

- If we select DP40 Pump from its graph, we see that this pump will need about 25 CFM of air at about 70 PSI supply pressure.